Увођење

Plastic straws are everywhere in the beverage, food service, and hospitality industries. Despite increasing scrutiny involving sustainable practices, plastic straws play an important role because they are inexpensive, easy to use, and can be produced at scale.

Knowing how plastic straws are made helps to acknowledge what goes on behind the scenes to make these products and why selecting the right straw manufacturing machine is important.

In this article, we will review the steps involved in the plastic straw manufacturing process, including what equipment is required at each step.

1. What Are Plastic Straws Made Of?

Plastic straws are made primarily from thermoplastics like

- Polypropylene (PP): This is the most popular plastic straw material because it is flexible, durable, and food safe.

- Polystyrene (PS): This is used for clear or rigid straws.

- Polylactic Acid (PLA): This biodegradable product made from renewable resources (like corn starch) is used to manufacture eco-friendly straws.

Each material has specific properties making it suitable for various applications like cold drinks, hot beverages, or specialty packaging. Choosing the right material affects how the straw performs and its impact on the environment.

2. Overview of the Plastic Straw Manufacturing Process

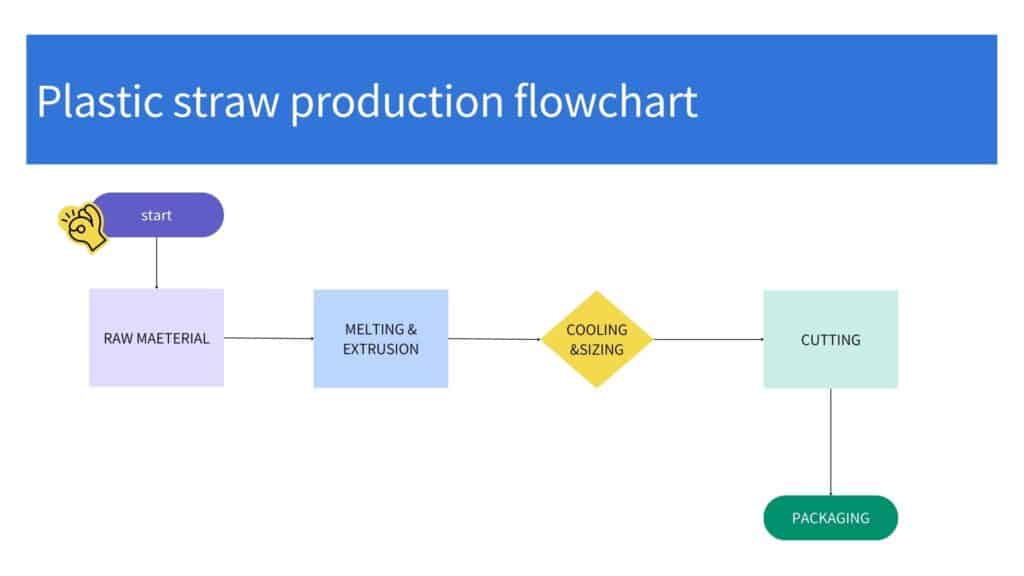

The typical plastic straw manufacturing process consists of the following steps:

- Raw material preparation

- Plastic extrusion

- Straw forming and calibration

- Cutting and finishing

- Quality control and packaging

Using a dependable straw manufacturing machine helps ensure that all of these steps run smoothly and efficiently.

3. Step-by-Step Explanation of Plastic Straw Production

3.1 Raw Material Preparation

Plastic production begins with high-quality resin pellets (usually polypropylene or polystyrene). These pellets are dried and tested to remove moisture from the material so that they melt uniformly during the extrusion process.

3.2 Plastic Extrusion: The Core Process

The extrusion process is the heart of plastic straw production, done with a машина за екструдирање пластике.

- Heating: The plastic pellets are fed into a heated barrel.

- Melting and mixing: A rotating screw in the barrel melts the pellets and mixes them into a uniform molten mass.

- Extrusion: The molten plastic is forced through a special die head designed for straws to make a continuous thin tube.

This continuous extrusion process is often called the operation of a straw extrusion machine.

3.3 Straw Forming and Calibration

After extrusion, the soft plastic tube is immediately cooled by passing it through a water bath. This cooling gives the tube its shape and helps it achieve the proper diameter and wall thickness.

- Calibrators are located in the cooling bath to ensure the size is consistent.

- It is also essential to cool and calibrate consistently to produce high-quality, straight straws that are not deformed.

The design and accuracy of the straw manufacturing machine will directly impact how well this phase of production goes.

3.4 Cutting and Finishing

Once the straw tubing has solidified, it enters the cutting area.

- Cutting: Rotary blades or servo-driven cutters cut the continuous tube into straws of specified lengths.

- Finishing: Depending on what the customer wants, the machine can create finished straws that are straight-cut, beveled (which makes puncturing the lids of drinks easier), or with specialty shapes on the ends.

Modern straw extrusion machines have precision cutters that ensure clean,burr-free edges.

3.5 Quality Control and Packaging

Quality control is critical to maintaining production standards.

- Inspectors check the straws to ensure they meet the proper diameter, length, wall thickness, and surface finish.

- Mechanical tests are conducted to check for strength, flexibility, and resistance to cracking.

Once the straws have passed inspection, they are counted, grouped, and packaged into bundles either by hand or by an automatic wrapping system.

4. Key Equipment in Straw Manufacturing

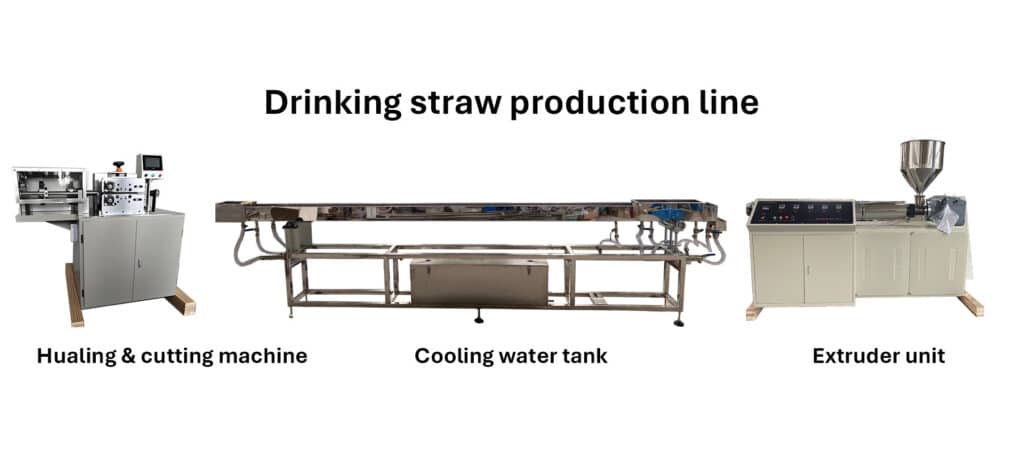

Plastic straw production consists of several machines that work together.

- Plastic extrusion machine: Melts the plastic and shapes it into continuous tubes.

- Cooling tank: Immediately solidifies the extruded plastic.

- Traction device: Pulls the straw tubing at a constant rate to keep it from deforming.

- Cutting unit: Cuts the straws to uniform lengths.

- Packaging system: Bundles the straws and prepares them for shipment.

Selecting a good quality straw manufacturing machine will also help you achieve better efficiency, less material waste, and greater consistency of product.

Want to select the right machine? Check out our guide on how to choose the best straw manufacturing machine for your factory to make a smart investment.

5. Common Questions About Plastic Straw Production

Why do some plastic straws crack easily?

Cracks are typically caused by poor quality raw materials or insufficient cooling during the extrusion process. A good quality plastic extrusion machine with stable temperature control will reduce this issue.

Regular maintenance is crucial for consistent quality. Learn more in our plastic extrusion machine maintenance guide for beginners.

How can I obtain a better surface finish on plastic straws?

Surface imperfections usually occur because of an inconsistent extrusion speed or improper cooling. The best straw extrusion machines have die designs and calibration systems that are optimized to deliver straws with smoother surfaces.

How many straws can I get out of a production line in a day?

Depending on the machine model and how well it is run, a typical high-speed straw manufacturing machine will produce about 100,000 to 300,000 straws per day.

Can I make colored straws or patterns with regular equipment?

Yes. You can add color masterbatches to the raw material prior to extrusion so that plastic extrusion machines will make straws in various colors. Certain systems can also produce straws with multiple colors or stripes by changing the extrusion die.

Закључак

Plastic straw manufacturing is a simple but technically sophisticated process that encompasses raw material preparation, extrusion, cooling, cutting, and packaging. All aspects of the production depend upon the quality and reliability of the equipment used—specifically, the plastic straw manufacturing machine. By selecting the right straw extrusion machine, you will achieve higher efficiencies, more consistent product, and lower costs to operate. Whether you are starting a new straw production line or upgrading existing equipment, good quality machinery is key to your success.

By understanding how plastic straws are produced, you will be able to make better decisions for your business to meet market requirements efficiently.

Still undecided between plastic and paper straw production? Read our in-depth comparison: straw extrusion machine vs. paper straw machine: which should you invest in?.