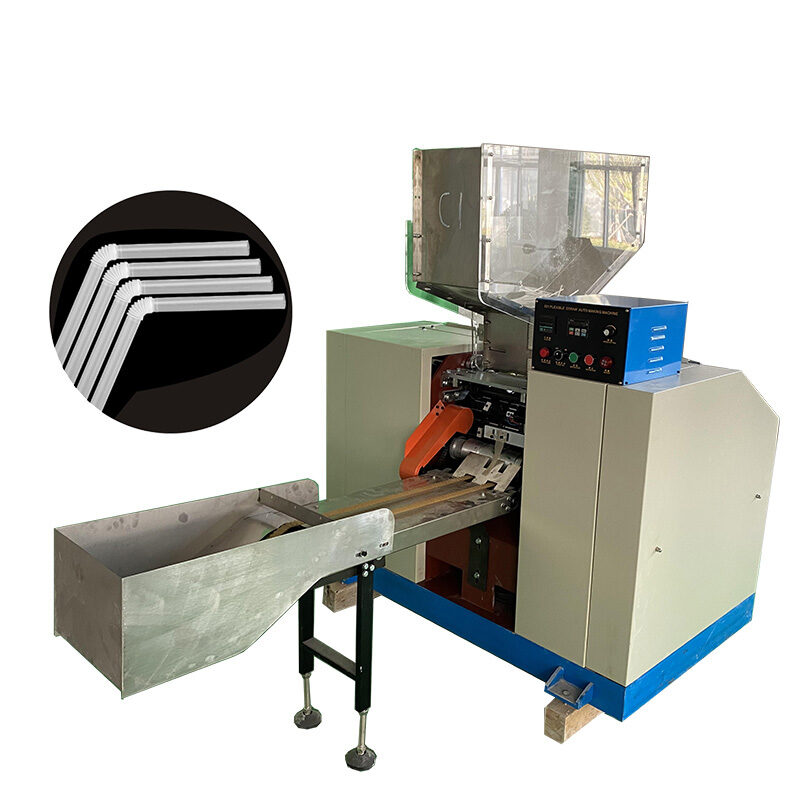

Efficient and Sustainable Paper Straw Production

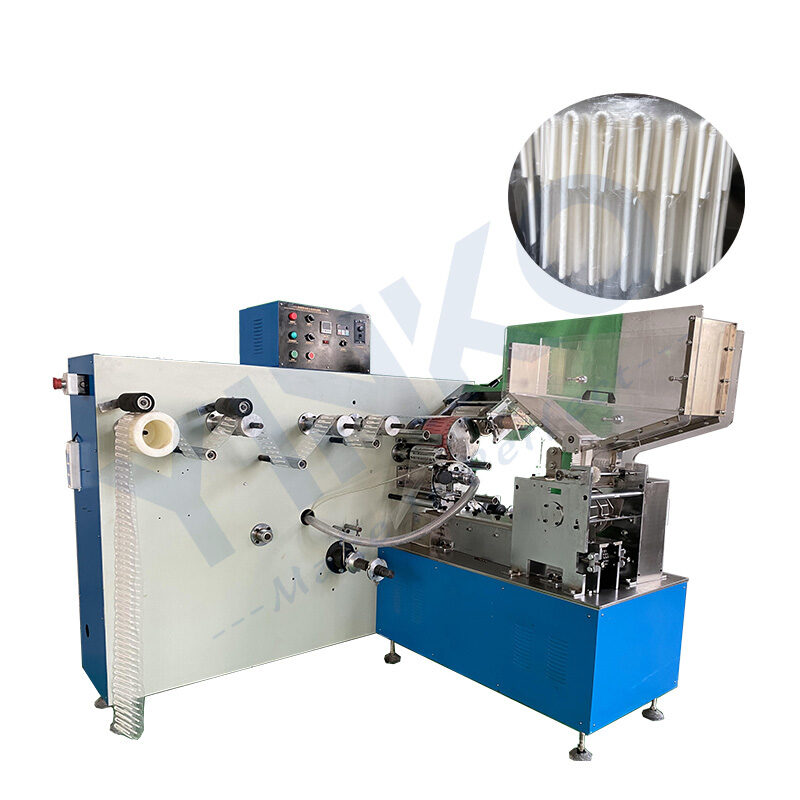

Welcome to the world of paper straw making machines - an innovative and efficient solution for businesses looking to switch to eco-friendly drinking straw. Our machines are designed to streamline the production process, incorporating a range of features to ensure smooth and reliable operation. The whole system includes a paper roll hanging bracket, capable of holding 4 layers of paper and auto-connecting/splicing for uninterrupted production. The glue station is made of stainless steel and features automatic glue feeding, while the winding and control mechanism ensures precision and efficiency in the manufacturing process. Our machines also feature a multi-cutting system, with 8 cutting knives equipped with dust and protective covers for worker safety. A conveyor and collector complete the system, allowing for easy transportation and storage of finished products. Discover the benefits of our state-of-the-art paper straw making machines today and make the switch to environmentally-friendly paper straws

From Left to right: Paper Roll brackets, Glue Station, Winding & control mechanism, Multi Cutting System, Conveyor, Collector

Why Choose Our Paper Straw Making Machine?

1

High-speed production up to 105m/min input and 80m/min output.

4

Auto paper roll connecting function with 4 layers for uninterrupted production.

2

8 cutting-knife system with new structure for easy air cylinder adjustment.

5

Auto lubrication grease feeding system for optimal cutting system performance.

3

5 servo motors for precise control of spiraling roller, cutting system, and more.

6

Famous brand electrical components, including Schneider, for top-notch quality.

Glue Station

- Aluminum and stainless steel frame;

- Stainless steel glue pot;

- Glue heating function(choosing choice);

- Glue recycle system

- Lubrication oil roller for inner paper strip;

- One pair roller ( rubber roller and steel roller) for filming glue on paper.

- 1 motor to drive glue roller;

- Easy to adjust glue quantity by adjusting the distance between two rollers.

Paper roll bracket with connecting function

- Aidez la machine à fabriquer des pailles en papier à ne pas cesser de fonctionner.

- Utilisez la détection automatique : lorsque le rouleau de papier est épuisé, le mécanisme coupe les extrémités de l'ancien rouleau de papier et connecte automatiquement le nouveau rouleau de papier.

- Dimensions plus petites, livraison facile et déplacement pour ajuster l'angle d'alimentation du papier.

- Simplicité de construction. Si le papier se casse, pas besoin de s'arrêter pour acheminer le papier de haut en bas, ce qui est compliqué.

- Force de déroulement constante des rouleaux de papier, pour permettre une alimentation plus fluide du papier.

- Notre propre brevet pour ce mécanisme de connexion, pas de copie d'autres marques, notamment européennes, donc pas de problème de brevet.

- Choix facultatif : mécanisme de connexion à 4 couches.

Steps of Paper Straw Making

1. Cutting the Raw Material into Strips

The process starts with large rolls of high-quality, food-safe paper. These rolls are cut into narrow strips of uniform width that will be used to make the straws.

2. Feeding Paper Strips into Brackets

The cut strips are placed in brackets in a straw-making machine. Depending on the design of the straw, these strips may consist of multiple layers (typically three or four) to improve durability and functionality.

3. Gluing the Paper Strips

A non-toxic, water-based adhesive is applied to the strips. This glue is important for holding the layers together as they are wound up. The glue must be safe for food contact because it will come in direct contact with beverages.

4. Spiral Winding Process

The glued strips are wound around a mandrel in a spiral fashion. This step shapes the strips into the cylindrical shape associated with straws and gives them structural integrity.

5. Shaping and Final Bonding

As the paper wraps around the mandrel, additional glue bonds all of the layers together securely. This step ensures that straw holds its shape and has enough thickness to be durable.

6. Cutting to Length

After being shaped, long tubes are cut into individual straws at a cutting station so that all straws produced will be uniform in length according to industry standards.

7. Drying Paper Straws

Once cut, straws are placed in drying chambers where they dry out after being cut . This step is important for setting up glue so that straws maintain their shape during use . Depending on manufacturer , this can involve natural air drying or temperature controlled drying units .

Watch Our Paper Straw Making Machine in Action

Paper Straw Making Machine Specification

| Modèle | YKZGJ-20 | ||

| Technical Parameter | Main Parts | ||

| Electric power | 380V/ 3phase/ 50Hz | PLC | PanKong |

| Electric consumption | 4.5-6.5Kw/h | Control screen | Schneider |

| FLA | 13.5A | Control program | GD-XJ2.0 |

| Speed | 0-80m/min ( output)

0-105m/min (paper feeding) |

Servo motor driver | Schneider |

| Paper layer | 2-4 layers | Servo motor | Schneider |

| Straw Diameter | 4.3--12mm (out diameter)

3.5--11.3 (inner diameter) |

Frequency converter | Schneider |

| Max thickness | 0.6mm-single side | Circuit breaker | Schneider |

| Min thickness | 0.2mm-single side | Relay | Schneider |

| Longueur de paille | 100--1400mm

Distance between 2 blades |

Signal sensor | Omron |

| Cutting method | 8 knife, pneumatic driving | Encodeur | Omron |

| Méthode de colle | Célibataire & double face | Pneumatic cylinder | AIRTAC |

| Length control | Encodeur | Bearing | HRB |

| Contrôle de vitesse | Servo tracking | Attached equipment/function | |

| Opérateur | 1 personne | Paper connecting function | Avoir |

| Fixation par mandrin | Pince à vis | Dust & protection cover | Avoir |

| Synchronism control | Servo belt | Winding roller cover | Avoir |

| Winding belt tension control | Hand wheel | Cutting knife cover | Avoir |

| Belt angle control | Hand wheel | Pull force tension sensor | Avoir |

| Lubrification | Lubrication grease | Auto lubrication grease | Avoir |

| Dimension and Weight | Constant rewinding force | Avoir | |

| Main part dimension | 3850×1200×1600mm | Mould Anti-vibration roller | Avoir |

| Land area dimension | 8000×4500×1900mm | Glue recycle pump | Avoir |

| Winding roller diameter | 215mm | Cutting system limitation rod | Avoir |

| Winding roller height | 120mm | Multi-control language | Avoir |

| Poids | 1400 KG | Stainless steel cover | Optional |

| Attached Spare Parts | |||

| Paper Straw Mould | 3 sets | Winding belt | 15 pcs |

| Cutting blades | 14 pcs | Boîte à outils | Avoir |

| Air cylinder | 1 pcs | Thinner pull rod clamp | 2 pcs |

| Double adhesive tape | Several for paper roll bracket connecting function | Metal adhesive glue | 2 bottle |

Pros & Cons of Paper Straw

Pros

- Les pailles en papier sont biodégradables, ce qui en fait une alternative écologique aux pailles en plastique qui peuvent mettre des centaines d'années à se décomposer.

- Les pailles en papier peuvent être recyclées, réduisant ainsi les déchets et contribuant à une économie plus circulaire.

- Les pailles en papier sont fabriquées à partir de ressources renouvelables, telles que la pâte à papier et les adhésifs à base de plantes, ce qui en fait un choix plus durable

Cons

- Les pailles en papier ne sont pas aussi durables que les pailles en plastique et peuvent devenir détrempées ou se désintégrer lorsqu'elles sont exposées à des liquides pendant des périodes prolongées.

- Les pailles en papier peuvent être plus chères que les pailles en plastique, ce qui peut dissuader certaines entreprises de faire le changement.

- Les pailles en papier ne conviennent pas aux boissons chaudes, car elles peuvent devenir molles et perdre leur forme lorsqu'elles sont exposées à la chaleur.

Utiliser des pailles en papier peut être un bon choix pour les personnes soucieuses de l’environnement et souhaitant réduire leurs déchets plastiques. En tant qu'alternative biodégradable et recyclable aux pailles en plastique, les pailles en papier peuvent contribuer à réduire l'impact négatif des plastiques à usage unique sur l'environnement.

En ce qui concerne l’avenir des pailles en papier, il est probable que la demande d’alternatives durables et respectueuses de l’environnement aux pailles en plastique continuera de croître, et les pailles en papier sont en passe de devenir un acteur clé sur ce marché. Cependant, il faudra peut-être relever des défis en termes de coût, de durabilité et de disponibilité pour garantir l’adoption généralisée des pailles en papier.

En outre, l'innovation et le développement continus dans le domaine des matériaux et des processus de fabrication durables pourraient conduire à la création de nouvelles alternatives améliorées aux pailles en plastique et en papier, ce qui pourrait façonner davantage l'avenir de l'industrie.

Build Trust with Customer Feedback

“We’ve been using YINGKE’s Paper Straw Making Machine for over a year now, and the results have been outstanding. The machine is incredibly fast, producing high-quality paper straws that are durable and meet our customers’ eco-friendly expectations. It has helped us scale up our production while maintaining a competitive edge in the market.”

— Mark Thompson, CEO,

“The customization options on YINGKE’s Paper Straw Machine have been a game-changer for our business. We can now offer various sizes and designs of paper straws, including custom-printed options, which have really boosted our sales. The machine is easy to operate, and the after-sales support has been fantastic.”

— Sophia Liu, General Manager

“As sustainability becomes more important to our customers, YINGKE’s Paper Straw Machine has allowed us to meet their needs with an eco-friendly alternative. The machine is efficient and energy-saving, and the paper straws we produce are of excellent quality, completely biodegradable, and sturdy enough for long-term use.”

— John Martinez, Operations Manager

“The reliability and speed of YINGKE’s Paper Straw Making Machine have exceeded our expectations. We’ve experienced minimal downtime, and the machine produces consistent, high-quality paper straws that meet all regulatory requirements. The transition to paper straws has been seamless, thanks to YINGKE’s support and superior machinery.”

— Emma Green, Production Head

Explore More Solutions

Looking for additional straw production solutions? Check out our range of machines designed to meet all your production needs.

Questions fréquemment posées

1. What materials does the Paper Straw Making Machine use?

The machine uses food-grade, eco-friendly paper that is biodegradable and compostable, ensuring compliance with environmental standards.

2. Quelle est la capacité de production de la machine?

The machine can produce up to 700 paper straws per minute, depending on the size and configuration of the straws.

3. Can I produce different sizes and designs of paper straws?

Yes, the machine is designed to create paper straws in various diameters, lengths by changing parts.

4. How energy-efficient is the machine?

The machine is equipped with energy-saving components and consumes 4.5KW-6.5 kW, making it both eco-friendly and cost-effective to operate.

5. Quel type de soutien après-vente offrez-vous?

We provide comprehensive after-sales support, including remote troubleshooting, spare parts supply, and on-site training for your team.

6. What's the lead time of your machine?

We normally deliver the machine in 35 days after down payment is received.

7. Do you provide any spare parts with the machine?

Yes, we will give some parts for free with the machine.