Introduction

Thanks to eco-friendly materials and the need for clean, efficient packaging, straw packing machines are now a must-have in the production of drinking straws for coffee shops, milk producers, and big straw companies needing dependable, flexible packaging for plastic, paper, PLA and PHA straws.

This article will discuss the major types of straw packing machines, the applications for each, and how to select the right solution for your output needs.

1. What Is a Straw Packing Machine?

A straw packing machine is a machine that wraps or packages drinking straws automatically. Depending on the style of machine, it can pack single straws or multiple straws into bags or put adhesive films on straws going into milk boxes (like Tetra Paks).

In addition to making packaging more hygienic and consistent, the straw packing machine enables manufacturers to increase production while lowering labor costs. Because of the world’s emphasis on making everything clean, particularly in food-related industries, packaging straws individually or in sealed bags is now a quality requirement, not just a nice-to-have.

2. Types of Straw Packing Machines

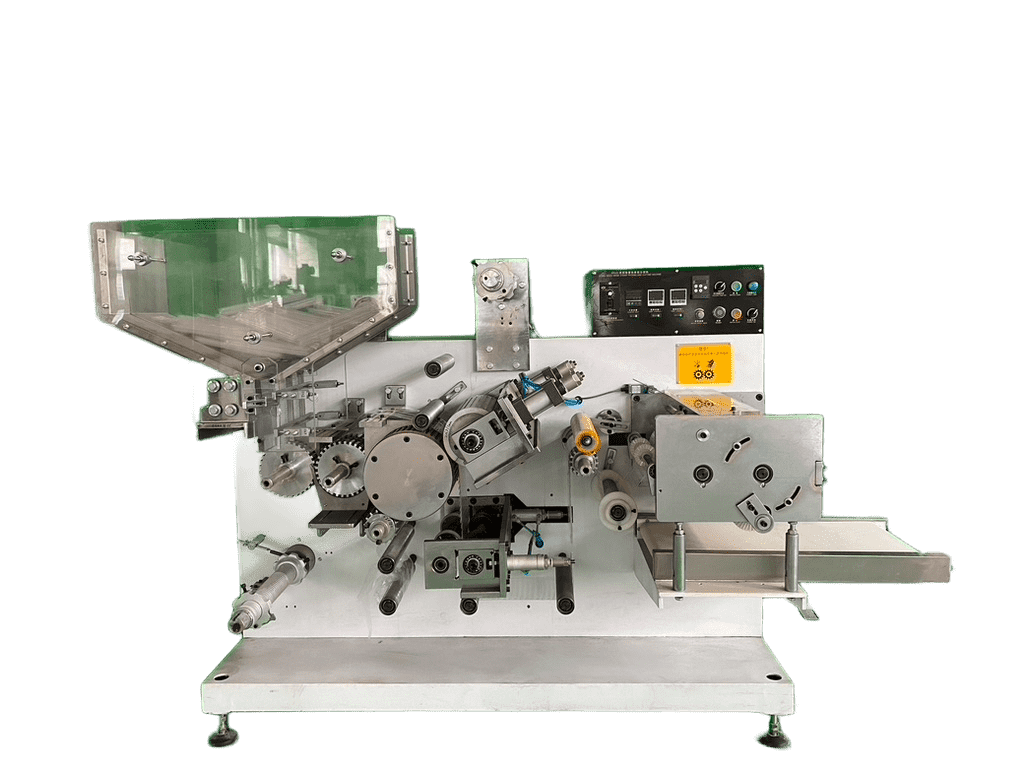

2.1 Single Straw Packing Machine

This is the style used by most straw manufacturers. A single straw packing machine can work with paper straws, plastic straws, PLA straws, and PHA straws. It wraps each straw individually, usually using film or paper roll material. It includes features like code printing, multi-language, continuous cutting, or piece cutting.

Because of its flexibility, it is usually the centerpiece of a straw making line. It comes in especially handy when hygiene, branding and customization of the product are important (i.e. restaurants, airlines or hotels that want to offer branded straws to their customers).

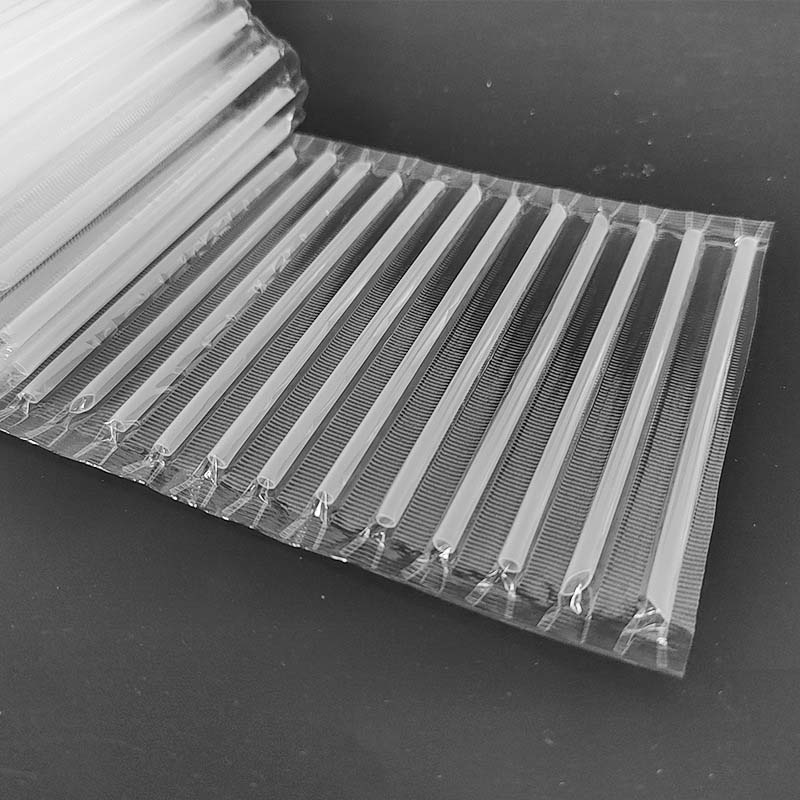

2.2 I-Shaped Straw Packing Machine (Four-Side Sealing Type)

The I-shaped straw packing machine provides a more sealed package using BOPP film and four-side sealing type. It packages straws individually in three formats:

- Continuous without cutting

- Long uncut strips

- Individually cut

- Easy tear pre-cut

This type of machine is used with brands that want a higher presentation quality, better sealing, and longer shelf life for packaged straws. The four-side sealing format not only looks better but also provides better barrier protection against dust, moisture, and contamination.

2.3 Tetrapak Straw Packing Machine

Designed specifically for U-shaped straws, the Tetrapak straw packing machine is commonly used in juice and dairy applications. These machines wrap and seal the straw in film, preparing it to be affixed with glue or heat onto drink cartons.

Whether they be juice boxes or milk cartons, this machine allows for fast and accurate packaging meant for high-speed filling lines. Some models also utilize intelligent tracking systems to apply glue and place the straws for minimal waste and better efficiency.

2.4 Multi-Straw Bag Packing Machine (With Linkage Option)

This machine is often used in tandem with a single straw packing machine. After straws are individually packed, they are transferred via conveyor to the bagging machine. There, the machine counts, forms a bag, fills it with a predetermined amount of straws, and seals and cuts the bag.

Ideal for bulk and retail, this system packs multiple straws in a sterile, single-unit format—ensuring hygiene, convenience, and faster shelf readiness. These machines have adjustable bag sizes, print registration, and a high-speed servo-controlled system, making them ideal for both domestic and export packaging.

3. Industry Applications

Various industries use straw packing machines, including

- Fast food and beverage service for plastic straws and PLA straws served with takeout cups.

- Retail packaging for paper straws sold individually in stores or online. Using custom-branded wrappers improves visibility of the product.

- Dairy and juice processing plants for flexible straws compatible with Tetrapak that get put on juice and milk cartons during the bottling process.

- Straw exporters or OEM suppliers for customers that require multi-language packaging, bar code printing, or selling straws together in retail packages.

- E-commerce and private-label brands that sell customized eco-friendly straw packs shipped directly to customers.

Thanks to the different types of machines that are available to manufacturers, they can match packaging requirements with material types, product sizes, and expectations of the end markets.

4. How to Choose the Right Straw Packing Machine Manufacturer

When choosing a company to purchase a machine from, price is only one consideration. Here are some others to keep in mind:

- Straw types. Make sure the machine can work with the types of straws you will use (paper, PLA, flexible U-shaped).

- Production volumes. Choose a machine that meets your daily needs and speed (300–800 pieces per minute or more)

- Level of automation. Look for features like auto-feed film, cut control, code printing, and fault detection.

- Customizable configurations. Machines that have modular upgrade capability (linkage with a bagging unit, optional punch heads, laser printing, etc.) provide more flexibility as production increases.

- After-sales support. Quick response times, availability of spare parts, remote troubleshooting capability, and the ability to ship parts globally are essential for keeping your operation running.

Reputable straw packing machine manufacturers will provide real customer references, demo machines, and technical drawings to assist you in your buying decision. In fact, some suppliers will let you set up virtual tours or live video demos to see their machines perform.

Conclusion & Recommendations

From individual wrapping to grouping retail bags and reducing them into Tetrapak-style solutions, various types of straw packing machines are available to meet the needs of today’s straw makers.

Narrow down your choices for the correct system based on straw types, end markets, and packaging needs. You might be able to get away with a single straw packing machine for smaller needs, but if you intend to go into industrial production or export, consider high-speed machines with enhancements that can include automatic bagging or four-side sealing.

Lastly, make sure to choose a manufacturer that has a proven track record of working with multiple kinds of materials, has experience with the custom automation that you may need, and can provide global service support.

If you want help figuring out the right machine, contact our team for guidance and product catalogs to check out.