Introduction

As environmental concerns and regulations change the drinking straw business, manufacturers have a critical decision to make: spend money on a straw extrusion machine for traditional plastic straws or switch to a paper straw machine to meet the growing demand for environmentally friendly products.

Selecting the right equipment will greatly impact your production efficiency, market reach, and profitability. This article will compare and contrast the two types of machines so you can make a wise investment that pays off well into the future.

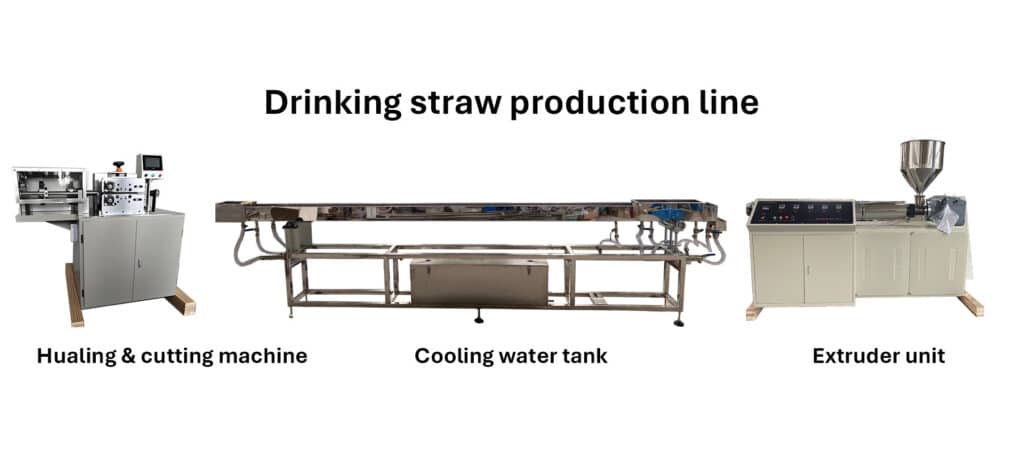

1. Overview of Straw Extrusion Machines (Plastic Straw Machines)

A straw extrusion machine is used mainly to make plastic straws out of materials like polypropylene (PP) or polystyrene (PS). The process entails melting plastic pellets and extruding them through a die to create long tubes of straw. Key features:

- Fast production: Plastic straw machines can produce as many as 850,000 straws in 10 hours (assuming 0.35 grams/straw and 30 kgs/hour output). – Inexpensive: PP and PE raw materials are relatively cheap.

- Product versatility: Can produce straight straws, flexible straws, and striped/colorful straws.

- Important note: Traditional plastic straw extrusion machines cannot run PLA material without modification because PLA requires more accurate temperature control and different processing.

Best suited for:

- Markets where plastic straws are still allowed.

- Companies selling to fast-food chains, beverage companies, and local catering companies.

2. Overview of Paper Straw Machines

A paper straw machine makes straws by bonding several layers of food-grade kraft paper together with water-based adhesives, forming them into tubes, drying them, and cutting them to the proper length.

Key features:

- Eco-friendly: Fully biodegradable and compliant with laws around the world banning plastic straws.

- Growing demand: Particularly in Europe, North America, and areas where environmental consciousness is growing.

- Customization options: Can make different diameters and colors and have printed designs on the straws.

Best suited for:

- Brands are trying to promote sustainability.

- Companies exporting to countries with strict environmental regulations like the EU and the U.S.

3. Key Differences Between the Two Machines

3.1 Production Process

- Straw Extrusion Machine:

- Continuous extrusion of melted plastic

- Straightforward operation; fewer steps (melt → extrude → cool → cut)

- Faster production speeds

- Paper Straw Machine:

- Multi-step process involving feeding paper, gluing it, rolling it, drying it and cutting it

- Must apply glue accurately and control the drying process

- Slower production rates than plastic extrusion

3.2 Cost Considerations

- Machine Cost:

- Plastic straw machines: $9,000–$18,000

- Paper straw machines: $30,000–$80,000

- Raw Material Cost:

- PP/PE pellets are cheaper than food-grade paper

- Production costs for paper straws are higher but they can be sold for a premium

- Operating Cost:

- It costs more to operate paper machines due to drying

- Plastic machines are less costly for energy and maintenance

3.3 Market Trends and Regulatory Impact

- Plastic Straws:

- Bans or restrictions in place in many countries (e.g., EU, some states in the U.S.)

- Still widely accepted in parts of Asia, Africa and Latin America

- Paper Straws:

- Strong growth trend in environmentally conscious markets

- Consumers gradually adapting in the face of issues with sogginess and mouthfeel

3.4 Profitability Analysis

- Plastic Straws:

- High volume, low-margin model

- Better fit for price-sensitive markets

- Paper Straws:

- Lower volume, higher-margin

- Perfect for brands that want to position themselves as sustainable and premium

4. Decision-Making Guide: Which One Should You Choose?

| Scenario | Recommended Investment |

|---|---|

| Targeting eco-friendly, premium markets (EU, US) | Paper Straw Machine |

| Serving local or developing markets with minimal plastic restrictions | Straw Extrusion Machine |

| Budget constraints but seeking fast ROI | Straw Extrusion Machine |

| Building a green brand image | Paper Straw Machine |

| Planning product line diversification (both plastic and paper) | Both Machines (phased investment) |

Additional considerations:

- Future-proofing your business may require preparing for an eventual transition toward biodegradable or compostable products.

- Understanding local and export regulations is critical before investing.

Conclusion

Both straw extrusion machines and paper straw machines have their unique benefits depending on the goals of your business, the demands of the market, and the regulatory environment.

- Buy a straw extrusion machine if you want to make a lot of plastic straws quickly and cheaply for markets that still allow plastic.

- Buy a paper straw machine if you want to be in alignment with global sustainability trends and sell to environmentally conscious consumers. By carefully evaluating your target market, your budget, and long-term vision, you can make the right investment that will lead to profitability and sustainability for many years to come.

Still not sure which machine is right for you? Contact us for a customized consultation and business analysis.

Already decided? Check our guide to choosing the best straw manufacturing machine to plan your next steps.