Introduction

In the world of straw manufacturing, a plasteksprutningsmaskin is a necessary evil to melt down plastic pellets and form them into long, continuous tubes that are cut into drinking straws.

In order to keep the machine running efficiently, to keep the product quality up, and to reduce downtime, you must maintain the machine.

In this maintenance guide for beginners, I’ll cover why it’s important to maintain a machine, what daily, weekly, and monthly tasks you should perform, and how to recognize the early signs of trouble with your straw extrusion machine.

1. Why Proper Maintenance Matters

Maintaining your plasteksprutningsmaskin provides numerous critical benefits:

• It reduces unexpected breakdowns. Preventive maintenance catches little problems before they become big problems.

• It ensures product consistency. Proper maintenance keeps extrusion temperature and pressure steady so you produce smooth, consistent straws.

• It extends the lifespan of your equipment. Well-maintained machinery will run reliably for years beyond their expected service lives.

• It saves you money on operational costs. If you can avoid major repairs and the associated downtime on production, you will save a substantial amount of money.

If you neglect maintenance, you will quickly lose production capacity, quality, and profits.

2. Daily Maintenance Checklist

Perform these tasks at the beginning and end of each working shift so your machine stays in good working order:

• Clean out the hopper and feeding zone. Make sure there are no leftover plastic pellets or dust because they can contaminate good product.

• Check the temperature control systems. Make sure heaters and sensors are not generating abnormal readings and that there isn’t damage.

• Lubricate moving parts. Ensure you’re putting appropriate lubricants on chains, belts, and gears in the traction and cutting units.

• Check the cooling system. Water in the cooling tank should be clean and flowing well so the straw cools consistently during production.

• Look for leaks. Check hydraulic lines and cooling hoses to make sure there aren’t drips or cracks.

Keeping a simple daily log can help operators stay consistent and catch early signs of trouble.

3. Weekly and Monthly Maintenance Tasks

In addition to daily care, you will schedule these deeper inspections:

Weekly

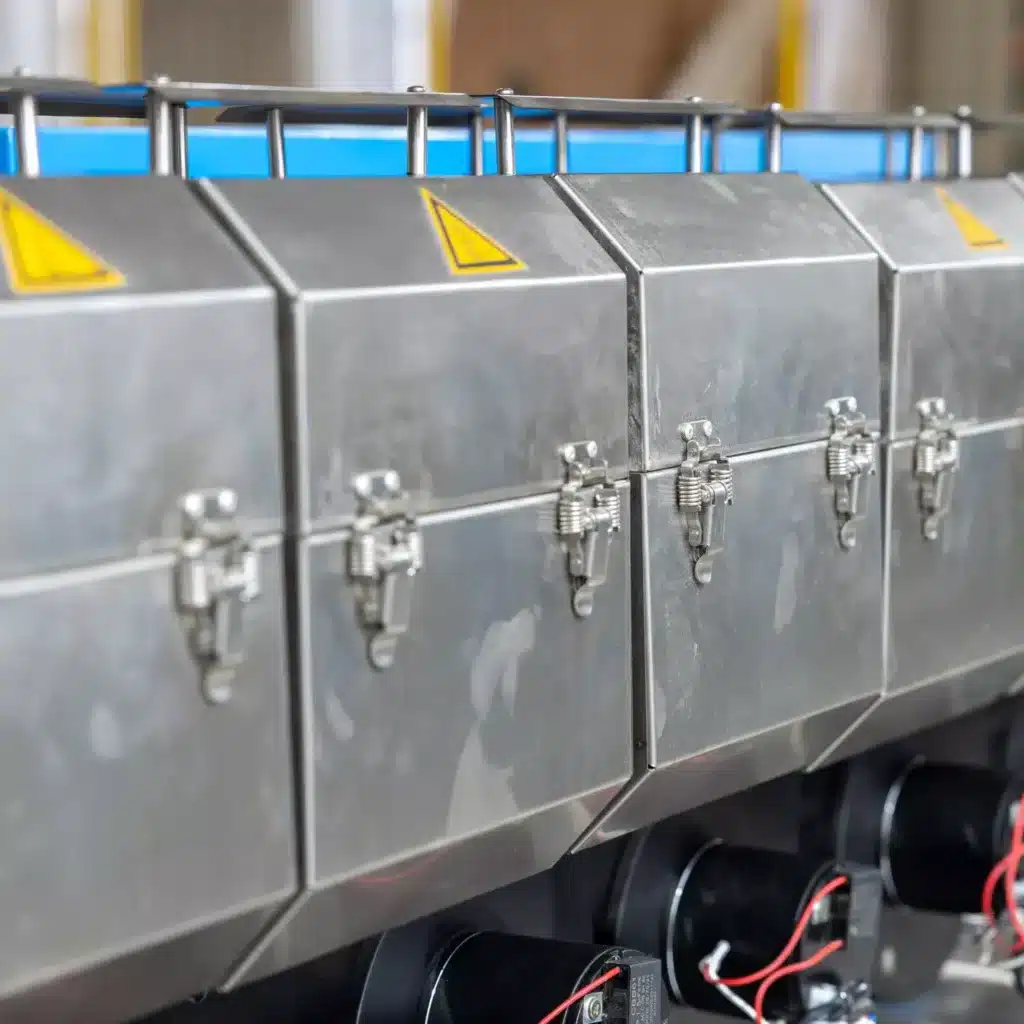

- Examine the screw and barrel. Look for wear, pitting, or buildup.

- Tighten fasteners. Bolts and clamps can loosen due to vibration over time.

- Clean the extrusion die. Buildup can form around the die affecting straw dimensions.

Monthly

- Calibrate sensors and controllers. Temperature and pressure sensors need to be accurately delivering readings.

- Inspect electrical components. Open the control panel to remove dust buildup and check connections.

- Flush the cooling system. Make sure to drain the water and refill with fresh water or coolant.

- Check traction and cutting devices. Replace or sharpen cutting blades as needed.

Setting calendar reminders will help make sure these tasks don’t get forgotten.

4. Common Signs of Potential Machine Issues

It is important to recognize problems early to save time and money. Watch for these warning signs:

- Unusual noises or vibrations. These may indicate loose parts or bearing failure.

- Temperature fluctuations. These can signal issues with heaters or sensors.

- Surface defects on straws. Lines, pits and rough finishes suggest problems with the screw, barrel, or die.

- Inconsistent straw diameter. These may be the result of uneven cooling or extrusion pressure issues.

- Pressure irregularities. An irregular extrusion pressure profile may indicate material blockages or worn components.

If you see any of these symptoms, stop production and investigate immediately.

5. Spare Parts and Preventive Planning

Keeping critical spare parts on hand will prevent long production slowdowns when you need to make repairs.

Critical spares include:

• Heating bands and temperature sensors.

• Extrusion screws and barrels.

• Die heads.

• Cutting blades and traction belts.

You should also

• Maintain a maintenance logbook noting inspections, maintenance actions taken, and parts changed.

• Schedule bi-annual professional inspections by your machine supplier or qualified technician.

Taking a few minutes a week to plan ahead will save you thousands of dollars in emergency repairs.

6. Best Practices for Long-Term Efficiency

Following best practices will ensure your straw extrusion machine operates at peak performance for years to come:

• Train your operators. Make sure every person operating the machine understands how to run the machine, what daily checks to perform and what to do in an emergency.

• Follow OEM guidelines. Always refer to the manufacturer’s maintenance manual for specific recommendations.

• Use quality lubricants and parts. Cheap stuff wears out faster and can void your warranty.

• Stay connected with your suppliers. Good manufacturers will provide ongoing updates, training, and service alerts at no cost.

• Have a preventive maintenance schedule. Don’t wait for a breakdown. Be proactive and preventive.

A culture of proactive maintenance makes things run smoother, creates a safer work environment, and drives better profit margins.

Conclusion

Maintaining your plastic extrusion machine isn’t just about preventing breakdowns. It’s about ensuring consistent, quality straw production and protecting your investment. By following daily, weekly, and monthly checklists, stocking key spare parts, and training your people, you can extend the life and performance of your straw extrusion machine.

In the highly competitive straw manufacturing market, a well-maintained machine can be the difference between thriving and merely surviving. Start implementing your preventive maintenance program now. Your profits will thank you!

Need professional advice or maintenance on your straw manufacturing equipment? Get in touch with us.

Are you planning to invest in a production line? Find out whether you should buy straw or paper straw machines .